Part marking isn’t a luxury—it's a necessity in many production

environments. Each marked part carries essential data, such as a serial number,

lot code, manufacturing date, or compliance stamp. This information helps

companies track every product from creation to end use, reducing the risk of

defects, improving quality assurance, and supporting maintenance or recall

processes.

More than just a label, a well-applied mark becomes a digital link

to your production history. And thanks to advances in part marking methods,

this process has become faster, more flexible, and more integrated than ever

before.

Streamlining Traceability with Automated Marking

Manual data tracking is slow, error-prone, and inefficient. Affordable Industrial marking products replace manual processes by enabling real-time,

automated traceability.

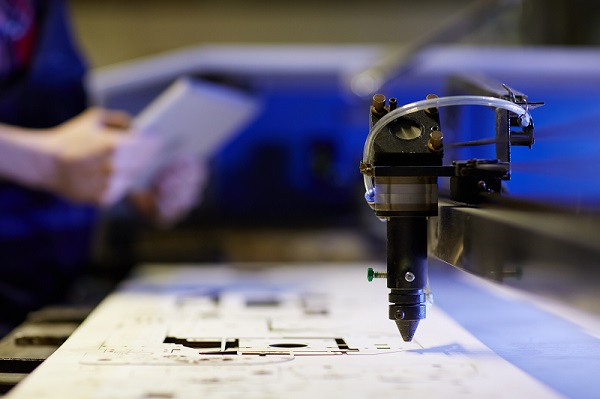

For instance, in a high-volume assembly line, laser or dot peen

systems can apply serial numbers to components in milliseconds—without

interrupting the flow of production. These marks are then automatically

captured and stored in a digital database, allowing teams to quickly access

product history at any stage.

This level of integration between marking and tracking not only

speeds up operations but also simplifies audits, quality checks, and

recalls—saving time and money across the board.

Reducing Production Errors Through Standardized Marking

Inconsistent marking creates confusion and delays. One part might

be misidentified or left unmarked entirely, leading to mix-ups during final

assembly or inspection. Industrial marking products help reduce these errors by

providing standardized, machine-readable marks that can be verified instantly.

When using methods like laser marking or inkjet coding,

manufacturers can program automated systems to apply consistent information to

every part. Built-in vision systems can scan and verify each mark in real time,

ensuring accuracy before a component continues down the line.

This precision reduces rework, minimizes scrap rates, and

contributes to a more reliable and predictable production flow.

Enhancing Workflow with Non-Contact and High-Speed Systems

Some part marking methods, such as engraving or stamping,

may slow down processes due to contact, vibration, or operator involvement.

Modern alternatives like laser marking or continuous inkjet systems offer

non-contact solutions that can operate at high speed without touching or

damaging the product.

Because there’s no mechanical pressure involved, non-contact

methods reduce the risk of part damage—especially when working with delicate

components or coated surfaces. At the same time, they speed up marking cycles

and require less downtime for tool changes or maintenance.

In turn, this allows production lines to run longer, with fewer

interruptions, and at higher output levels.

Flexibility for Customization and On-Demand Changes

One of the key advantages of today’s industrial marking products

is their adaptability. Unlike traditional stamping or labeling systems, digital

marking technologies can be updated in seconds to apply different data, designs,

or batch information.

For manufacturers producing small batches or handling multiple

product variations, this flexibility is essential. Operators can switch from

one marking pattern to another without halting production or retooling

machines—an invaluable capability in just-in-time and lean manufacturing

environments.

Such adaptability not only increases efficiency but also supports

mass customization, which is becoming increasingly popular in industries like

electronics, automotive, and consumer goods.

Improving Compliance Without Slowing Down Operations

Meeting regulatory standards can be time-consuming, especially in

industries like aerospace, medical, or defense. However, modern part marking

methods allow companies to meet strict marking requirements without

sacrificing speed.

Systems such as laser etching or dot peen marking can apply

precise, compliant marks that meet ISO, FDA, or MIL-STD guidelines. What’s

more, integrated software ensures that data is accurate and formatted

correctly, reducing the burden on operators and quality teams.

By aligning marking processes with regulatory needs from the

outset, manufacturers avoid last-minute delays, fines, or compliance

failures—keeping projects on time and within budget.

Lower Maintenance and Long-Term Cost Efficiency

Older mechanical marking systems often require frequent

calibration, part replacement, or downtime for servicing. In contrast, newer industrial

marking products offer enhanced reliability and minimal maintenance.

Laser marking systems, for example, can operate for tens of

thousands of hours without requiring tool changes. Inkjet systems now come with

auto-cleaning heads and predictive maintenance features. This reliability means

fewer breakdowns, more consistent output, and lower total cost of ownership

over time.

While initial investment in modern marking equipment may be

higher, the long-term savings from increased uptime and lower maintenance costs

are significant.

How Industrial Marking Supports Smart Manufacturing

As factories become more connected, part marking systems are

increasingly integrated into the broader digital ecosystem. Marking machines

now communicate directly with manufacturing execution systems (MES), enterprise

resource planning (ERP), and quality control platforms.

With real-time data exchange, manufacturers can:

- Track

parts across global supply chains

- Adjust production flows

dynamically

- Detect defects early and trace them back to their

origin

This data-driven environment supports predictive analytics and

continuous improvement, cornerstones of Industry 4.0 and smart manufacturing.

FAQs: Industrial Marking and Production Efficiency

1. How do industrial marking products improve workflow?

hey automate identification processes, reduce manual errors, and

integrate with tracking systems to streamline operations from start to finish.

2. Which marking method is best for high-speed production?

Laser and continuous inkjet systems are ideal for fast,

non-contact marking that doesn't slow down the line.

3. Can marking systems be customized for different parts?

Yes, modern systems support on-demand data changes, making them

perfect for batch variation and custom production.

4. Are these systems compatible with automation?

Absolutely. Most industrial marking products are designed for full

automation and integrate easily with robotic and smart factory systems.

5. How does marketing affect product quality?

They ensure consistent, readable markings that help maintain

traceability, prevent mix-ups, and reduce production errors—ultimately

supporting better product quality.

Conclusion

Production efficiency is no longer just about speed—it’s about

smart, connected, and accurate systems that can adapt and scale. Industrial

marking products, when used with the right part marking methods,

play a vital role in optimizing processes across manufacturing sectors.

From reducing errors and downtime to enabling compliance and traceability, these systems offer real value in improving both operational output and bottom-line performance. As manufacturers embrace digital transformation, investing in high-quality marking solutions will continue to be a key step toward future-ready production.